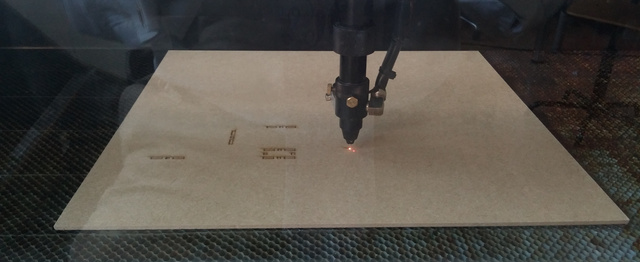

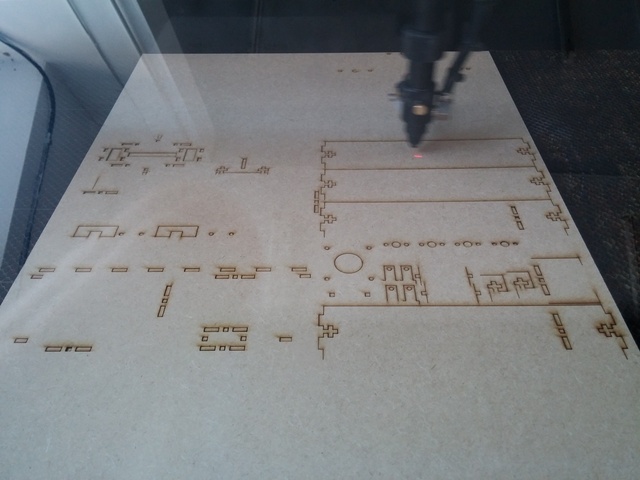

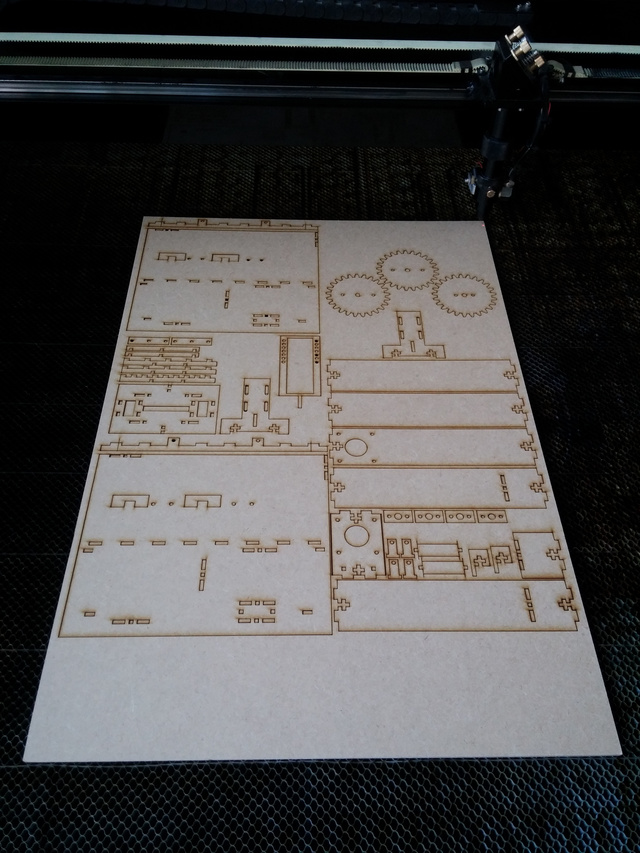

Time to lasercut a new frame, as well built it uncovered a few issues/bugs than need to be fixed.

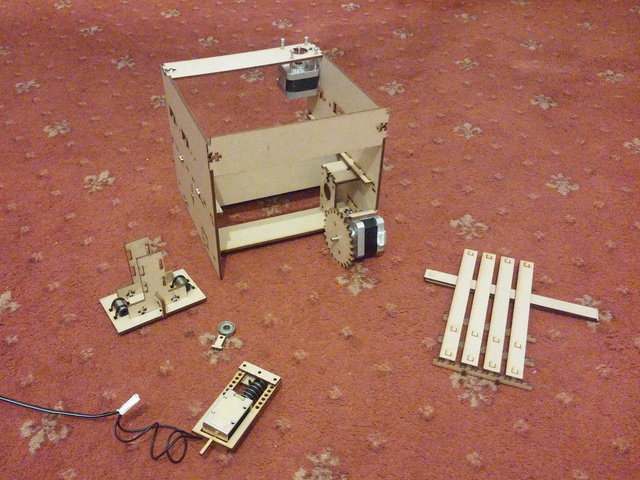

I then put the pieces together, which generated some issues to be raised in github.

The biggest issues was that MDF is unforgiving compared with pine, and the kurf needs to be bigger.

Issue #1

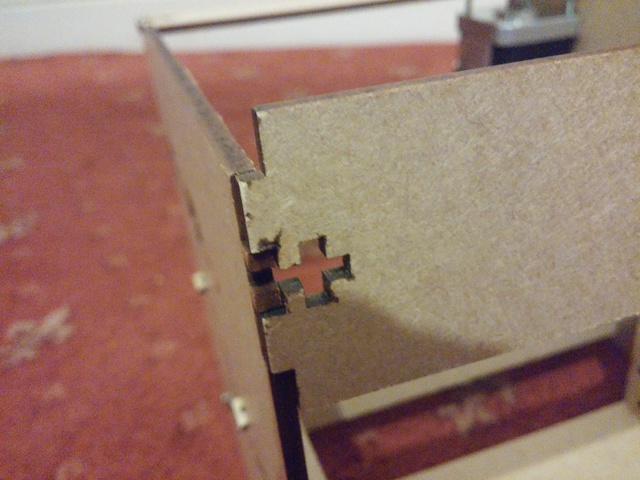

https://github.com/bmsleight/pixelate-toast/issues/1 The tracks for some reason the inner cuts were missing on one side

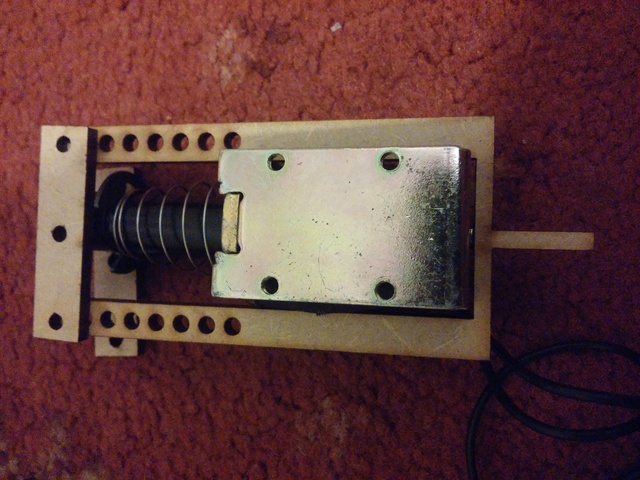

Issue #2

https://github.com/bmsleight/pixelate-toast/issues/2 The space around the solenoid needs to be bigger to allow for wiring from the solenoid.

Issue #3

https://github.com/bmsleight/pixelate-toast/issues/3 The space on the shuttle needs to be bigger if the plunger is made bigger (See issue 2)

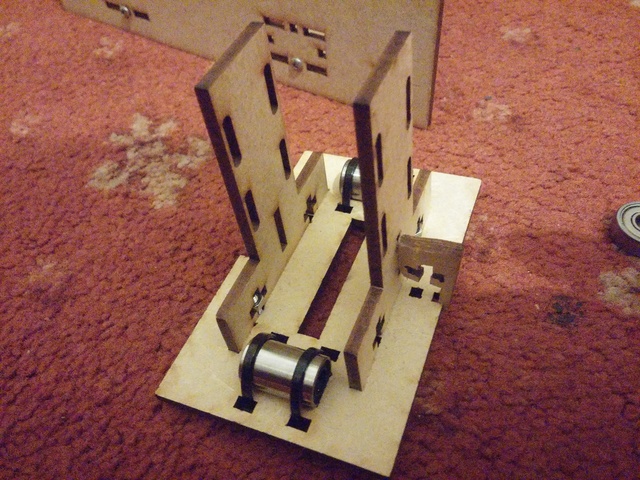

Issue #4

https://github.com/bmsleight/pixelate-toast/issues/4 The bearing are I have are the wrong size, although nothing wrong with the model - I just have to order some http://www.ebay.co.uk/sch/i.html?&_nkw=688zz

Now ordered - closed

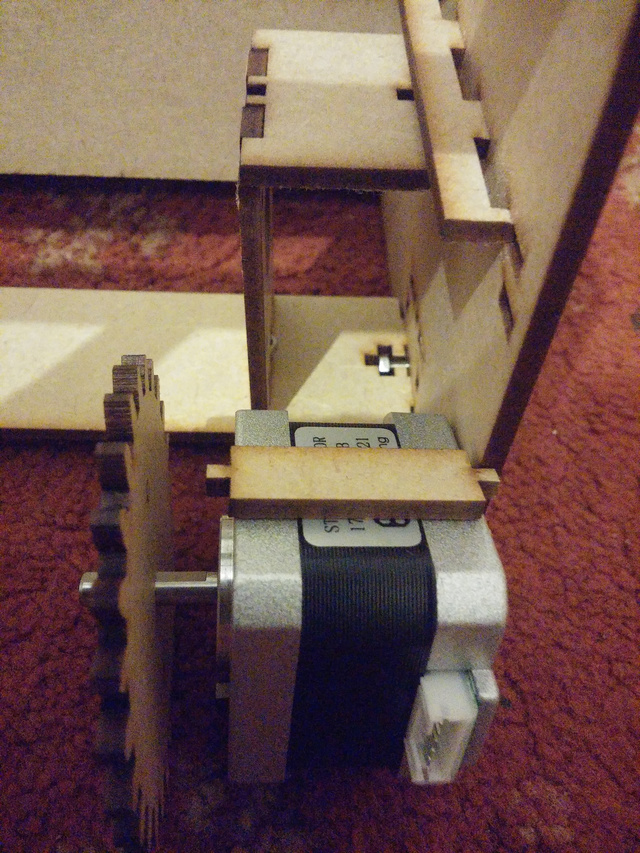

Issue 5

https://github.com/bmsleight/pixelate-toast/issues/5 Motor to control the shuttle going across, can not be attached from the back. So I need to move the support down. This will also have the benefit of having the support not at the far edge of the sides, which keep the captive nuts in place.

Issue 6

https://github.com/bmsleight/pixelate-toast/issues/6 Gap for gear motor not big enough. The small piece on top of the motor, used to support the motor is the right size, but the gap in the background is 3mm (standard thickness too small). Need to move the captive nut hole and extend the top piece.

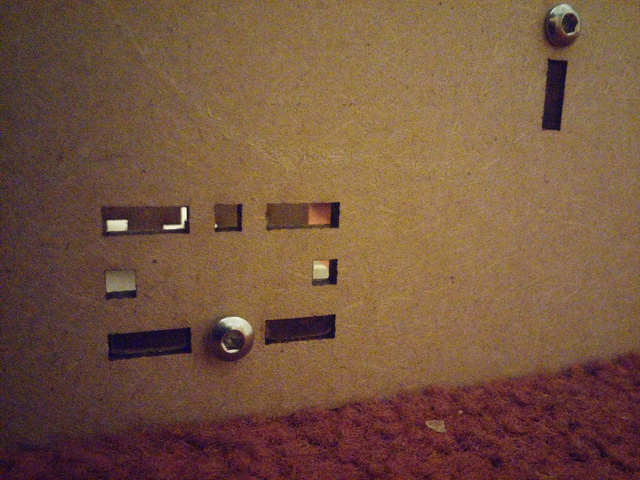

Issue 7

https://github.com/bmsleight/pixelate-toast/issues/7 Extra holes not required, no captive nut at the upper position.

Issue 8

https://github.com/bmsleight/pixelate-toast/issues/8 Support too high and standing proud from the sides. Also captive nut is on the edge which means the nut can pop out easy. Solution, move the connection in and down, but check for clearance with toast.

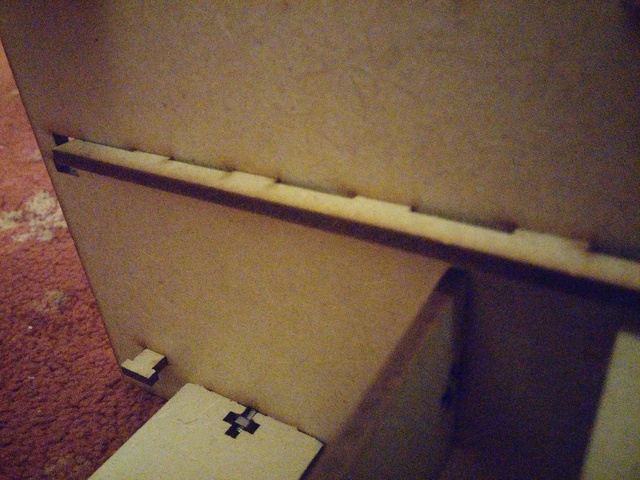

Issue 9

https://github.com/bmsleight/pixelate-toast/issues/9 Side rails do not fit well. This is a manifestation of one of the biggest problems, the MDF is either a little bigger then 3mm or the kerf is less than expected. Solution to make less slots and make the hole part bigger.

Issue 10

https://github.com/bmsleight/pixelate-toast/issues/10 Need to order some bigger screws and rods as well as screw to connect the solenoid.

Issue 11

https://github.com/bmsleight/pixelate-toast/issues/11 Need to add a brace to the wooden gear.

Issue 12

https://github.com/bmsleight/pixelate-toast/issues/12 The material is not 3mm, but 3.10 -> 3.20 mm. This makes the parts harder to fit together.